Electronic Control

The 220/240V power supply is connected to the motor control module, which rectifies to DC for use by its own controller and peripherals, and also for the sensor and display module. The motor control module has an optically isolated serial communications port to the sensor module from which it receives commands for operating the drum motor and the heater(s). The motor control module does the actual control of those devices.

The sensor module is responsible for the overall control of the dryer, including the input and output of all other peripherals. The sensor module controls the lid lock and the drum door actuator, senses the drum position and speed, measures the exhaust duct temperature through the exhaust sensor and measures the dampness of the clothes load via the sensor bars.

The algorithm for when the heaters are turned on and off, and also for the speed and direction of the motor, is implemented within the sensor module, but the switching of the elements, and control of the motor, is done by the motor control module in response to the commands from the sensor module. When the mains power is first applied to or restored to the sensor module, the dryer will Endeavour to continue operating from when the power was lost. If mains power was lost during a drying cycle, it will continue to dry to the same set dryness level, otherwise the machine will return to have the drum door open and the lid unlocked.

The display module incorporates push buttons and a LCD display, which acts as an interface that passes user settings to the sensor module. Once Start/Pause has been pressed animations appear on the screen demonstrating the function that is being performed, alongside these animations is ongoing information regarding the chosen drying cycle etc.

The 220/240V power supply is connected to the motor control module, which rectifies to DC for use by its own controller and peripherals, and also for the sensor and display module. The motor control module has an optically isolated serial communications port to the sensor module from which it receives commands for operating the drum motor and the heater(s). The motor control module does the actual control of those devices.

The sensor module is responsible for the overall control of the dryer, including the input and output of all other peripherals. The sensor module controls the lid lock and the drum door actuator, senses the drum position and speed, measures the exhaust duct temperature through the exhaust sensor and measures the dampness of the clothes load via the sensor bars.

The algorithm for when the heaters are turned on and off, and also for the speed and direction of the motor, is implemented within the sensor module, but the switching of the elements, and control of the motor, is done by the motor control module in response to the commands from the sensor module. When the mains power is first applied to or restored to the sensor module, the dryer will Endeavour to continue operating from when the power was lost. If mains power was lost during a drying cycle, it will continue to dry to the same set dryness level, otherwise the machine will return to have the drum door open and the lid unlocked.

The display module incorporates push buttons and a LCD display, which acts as an interface that passes user settings to the sensor module. Once Start/Pause has been pressed animations appear on the screen demonstrating the function that is being performed, alongside these animations is ongoing information regarding the chosen drying cycle etc.

Loading

The dryer always stops with the drum door open. The user places the drying load into the drum, closes the lid, pushes the Power button, selects the required cycle and presses the Start/Pause button. The lid will lock, the drum will rotate and the door grabber will slide the drum door closed. The door grabber will then move clear of the drum.

The dryer always stops with the drum door open. The user places the drying load into the drum, closes the lid, pushes the Power button, selects the required cycle and presses the Start/Pause button. The lid will lock, the drum will rotate and the door grabber will slide the drum door closed. The door grabber will then move clear of the drum.

Lid

Lock Control

The Intuitive dryer has a lock installed in the lid to provide added safety while the dryer is operating. It ensures that the lid cannot be opened while the drum is rotating. A Lid lock symbol (padlock) appears in the

corner of the screen when locked (it disappears when unlocked). If the lid lock symbol is flashing, the lid is in the process of being unlocked. During this stage, the lid still cannot be lifted.

The Intuitive dryer has a lock installed in the lid to provide added safety while the dryer is operating. It ensures that the lid cannot be opened while the drum is rotating. A Lid lock symbol (padlock) appears in the

corner of the screen when locked (it disappears when unlocked). If the lid lock symbol is flashing, the lid is in the process of being unlocked. During this stage, the lid still cannot be lifted.

The

lid lock is a mechanism driven by a DC solenoid and prevents the lid being

opened when the drum is rotating. If the lid lock mechanism is not engaged for

any reason, including open circuit or short circuit, a “Locked” is not assumed.

If unable to lock after the user has requested a start, a User Warning will be

given, and a fault code will get written to memory. The lid must be closed before the drying

cycle can start. If Start/Pause is pressed with the lid open, the machine will

beep and a message will appear in the display screen saying “Please close the

lid and press START/PAUSE”. Once the lid has been closed and tart/Pause has

been pressed, the lid lock will be activated and the drying cycle will

begin. If the power fails, either from a

power cut or having been switched off at the wall, the lid may be opened. In

some circumstances the drum door may not be in the open position. When the

power is restored the dryer will automatically recommence the drying cycle as

long as the lid is shut.

If

it is absolutely necessary to remove the load before the power is restored,

follow the steps below:

1. Ensure the dryer is disconnected from the power supply.

2. Open the lid (this will already be unlocked).

3. On the left hand side of the dryer there is a thumb tab that appears when the drum is not open. Press the thumb tab and rotate the drum by hand towards the back of the machine.

4. Hold the thumb tab down until the drum door starts opening.

5. Keep rotating the drum until the door is fully open and the drum comes to a stop.

6. The clothes can now be removed.

7. Close the lid once the clothes have been removed.

8. Re-connect the power supply to the dryer.

The drum door will automatically close and the dryer will resume normal operation when power is restored.

1. Ensure the dryer is disconnected from the power supply.

2. Open the lid (this will already be unlocked).

3. On the left hand side of the dryer there is a thumb tab that appears when the drum is not open. Press the thumb tab and rotate the drum by hand towards the back of the machine.

4. Hold the thumb tab down until the drum door starts opening.

5. Keep rotating the drum until the door is fully open and the drum comes to a stop.

6. The clothes can now be removed.

7. Close the lid once the clothes have been removed.

8. Re-connect the power supply to the dryer.

The drum door will automatically close and the dryer will resume normal operation when power is restored.

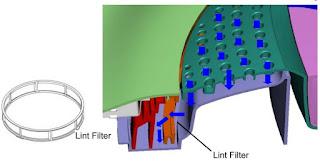

Lint

Filter

Lint laden air passes through the small holes in the outlet end of the drum (the small holes around the lint bucket). The lint removal system is directly behind these holes. As this air moves through the holes

it is forced through the lint filter. The fan then sucks the air down through the duct and out the back of the dryer. The lint filter in the IntuitiveTM dryer is circular and is positioned next to the drum. When the drum

rotates the lint filter rotates with it. The filter is made of very fine 200-micron mesh. All clothes dryers produce potentially flammable lint. Use of a fine mesh enables a lint filter to catch more lint from the air before it reaches the exhaust ducting. That reduces the possibility of any blockages or hazards caused by the accumulation of lint.

Lint laden air passes through the small holes in the outlet end of the drum (the small holes around the lint bucket). The lint removal system is directly behind these holes. As this air moves through the holes

it is forced through the lint filter. The fan then sucks the air down through the duct and out the back of the dryer. The lint filter in the IntuitiveTM dryer is circular and is positioned next to the drum. When the drum

rotates the lint filter rotates with it. The filter is made of very fine 200-micron mesh. All clothes dryers produce potentially flammable lint. Use of a fine mesh enables a lint filter to catch more lint from the air before it reaches the exhaust ducting. That reduces the possibility of any blockages or hazards caused by the accumulation of lint.

There is a scraper situated on the top of the lint collecting housing which the filter moves past. Where the lint on the filter builds up, the lint begins to touch the scraper, and is automatically scraped off. Because the scraper is directly above the lint bucket it falls straight in. The scraper helps achieve consistent airflow throughout the drying cycle by continuously removing any accumulated lint from the mesh of the filter.

The dryer user manual and lid label instruct the user to empty the lint bucket before the lint reaches the top of the transparent part of the bucket. If the lint bucket overflows due to the user not emptying it, the Intuitive dryer can clear itself. The user just needs to empty the bucket and run the dryer on a cycle for approximately 20 minutes. The dryer will free all the trapped lint and will re-deposit it back into the lint bucket.

The

Intuitive dryer will signal a reminder to the user to empty the lint bucket

after every 5 cycles. This reminder is automatically selected when the customer

receives the dryer. To turn this

reminder off, scroll to Options screen 4, press the Adjust button to select

Off, then press Home to save the setting.

Airflow

An intake grill at the bottom rear of the cabinet provides an entry point for the airflow through the dryer via four large louvered slots. Additional air is drawn in at the front of the cabinet under the front panel. A fan on the exhaust side of the drum draws the air over the heating elements located in a combustion chamber, through an inlet duct and into the drum. The air exits the drum through a self-cleaning lint filter in the drum outlet duct, then passes through the fan housing and out the rear exhaust vent situated at the bottom rear of the cabinet.

An intake grill at the bottom rear of the cabinet provides an entry point for the airflow through the dryer via four large louvered slots. Additional air is drawn in at the front of the cabinet under the front panel. A fan on the exhaust side of the drum draws the air over the heating elements located in a combustion chamber, through an inlet duct and into the drum. The air exits the drum through a self-cleaning lint filter in the drum outlet duct, then passes through the fan housing and out the rear exhaust vent situated at the bottom rear of the cabinet.

Auto sensing is automatically selected when the Intuitive dryer is turned on.

The user can select a time dry option of 20, 40 or 80 minutes through the

Options menu. Auto sensing of the clothes load dryness level is achieved by

touch sensors that sense the moisture content of the load. An exhaust

temperature sensor is used to monitor the exhaust temperature. The controller

limits the temperature to what is required for the various cycles and

determines what elements are used. An

auto reset thermostat located on the heater housing also limits the heat into

the dryer, but if it fails to operate, them a manually resettable thermostat

also situated on the heater housing will trip at 100oC, turning off the heat to

protect the clothes.

Cool

Down

The dryer enters a cool down period at the end of the cycle. During this period the dryer continues to run with the heating elements/burner turned off, blowing ambient air through the load to help prevent creasing.

Autosensing: If any Auto Sensing cycle has been selected, the cool down period will continue until the exhaust temperature drops to 35oC. However if this temperature is not achieved after 10 minutes, the cycle will stop. This would occur if the ambient temperature was above 35 oC. Timed Dry: If an 80 minute or 40 minute Timed Dry cycle has been selected, the cool down period will run for the last 10 minutes of that cycle. If a 20 minutes Timed Dry cycle has been selected, the cool down period will run for the last 5 minutes.

The dryer enters a cool down period at the end of the cycle. During this period the dryer continues to run with the heating elements/burner turned off, blowing ambient air through the load to help prevent creasing.

Autosensing: If any Auto Sensing cycle has been selected, the cool down period will continue until the exhaust temperature drops to 35oC. However if this temperature is not achieved after 10 minutes, the cycle will stop. This would occur if the ambient temperature was above 35 oC. Timed Dry: If an 80 minute or 40 minute Timed Dry cycle has been selected, the cool down period will run for the last 10 minutes of that cycle. If a 20 minutes Timed Dry cycle has been selected, the cool down period will run for the last 5 minutes.

Cycle Cool Down

Auto Sensing Cool down will last until the exhaust temperature drops to 35oC or 10 minutes, whichever occurs first.

Timed Dry 80 Minutes 10 Minutes

Timed Dry 40 Minutes 10 Minutes

Timed Dry 20 Minutes 5 Minutes

Drum Parts.

1. Drum Inlet End: Allows inlet air to pass through. This is how air enters the drum. It also houses the inlet central bearing assembly, about which the drum rotates.

2. Drum End Outlet: Provides the route for air to exit the drum as well as securing the lint filter. The outer face has dimples, which are collectively referred to as “the drum tachometer”. The central flange of the drum end outlet is supported and guided by seven bearing pads, which are mounted in the outlet duct.

3. Vanes: Encourage clothes to tumble during the drying cycle.

4. Drum Door: Slides back along grooves in the bridge to provide access into the drum.

5. Door Bracket: Secures and seals the drum in the closed position and houses components for latching the door.

6. Hinge Arm: Part of the door assembly, which is contacted by the door grabber for opening and closing the door. It also latches the door closed over the end of the track.

7. Locking Bar: Attached to its ends are the hinge arms. Its function is to hold these hinges in the correct orientation.

8. Hinge Spring: Springs the hinge arm down to ensure latching when the door is closed.

There

is also a Drum Door Scraper that prevents clothes from being drawn into the gap

between the drum and the door when the door is opening, and a Key Bracket that

prevents the door from closing when the clothes are protruding.

Drum

Control.

The drum is coupled to a three phase induction motor by way of a pulley on the motor shaft, which drives via a “V” belt and belt tensioned system. The motor control module controls the motor by generating the three phases from a high voltage rectified DC rail. When tumble drying, the drum is tumbled at 47 RPM, during opening and closing at 5 RPM, and at other speeds as required and requested from the sensor module. Feedback on speed is via the drum tachometer signal, which comes via the sensor module.

When drying, the drum rotates in the door closing direction for 4 minutes, after which it coasts to stop and reverses for 40 seconds, then coasts to stop before repeating the reversing throughout the drying and cooling cycle. The reversing of the drum direction reduces tangling

The drum is coupled to a three phase induction motor by way of a pulley on the motor shaft, which drives via a “V” belt and belt tensioned system. The motor control module controls the motor by generating the three phases from a high voltage rectified DC rail. When tumble drying, the drum is tumbled at 47 RPM, during opening and closing at 5 RPM, and at other speeds as required and requested from the sensor module. Feedback on speed is via the drum tachometer signal, which comes via the sensor module.

When drying, the drum rotates in the door closing direction for 4 minutes, after which it coasts to stop and reverses for 40 seconds, then coasts to stop before repeating the reversing throughout the drying and cooling cycle. The reversing of the drum direction reduces tangling

When creaseables is selected, at the end of the cycle the heaters are switched off, the drum then rotates in one direction for 30 seconds, then stops for 5 minutes without opening the drum door. Then it goes in the opposite direction for 30 seconds, then pauses again before turning off. If the user does not remove the clothes load, the cycle is repeated 255 times, which take approximately 23 hours. The drum tachometer uses pressed “dimples”, formed directly into the drum end outlet, spaced every 2 degrees to provide positioning information while also providing speed data. There is a 15 degree “gap” to provide the reference for absolute position. An infrared diode and optical receiving transistor provide the reading of the “dimples.” The digital signal is output to the motor control module, which uses the signal for speed controlling the drum. The drum position is monitored by the sensor module, which uses the position for both speed commands and drum door actuator control.

Contd: