AMPLIFIER

Stereo

mode 300 W + 300 W (4 Ω at 1 kHz, THD 10 %)

Front

300 W + 300 W (4 Ω at 1 kHz, THD 10 %)

Woofer

400 W (3 Ω at 200 Hz, THD 10 %)

1)

The pick-up incorporates a strong magnet, and so should never be brought close

to magnetic materials.

2)

The pick-up should always be handled correctly and carefully, taking care to

avoid external pressure and impact. If it is subjected to strong pressure or

impact, the result may be an operational malfunction and/or damage to the

printed-circuit board.

3)

Each and every pick-up is already individually adjusted to a high degree of

precision, and for that reason the adjustment point and installation screws

should absolutely never be touched.

4)

Laser beams may damage the eyes!

Absolutely

never permit laser beams to enter the eyes!

Also

NEVER switch ON the power to the laser output part (lens, etc.) of the pick-up

if it is damaged.

NEVER

look directly at the laser beam, and don’t allow contact with fingers or other

exposed skin.

5)

Cleaning the lens surface

If

there is dust on the lens surface, the dust should be cleaned away by using an

air bush (such as used for camera lens). The lens is held by a delicate spring.

When cleaning the lens surface, therefore, a cotton swab should be used, taking

care not to distort lens.

6)

Never attempt to disassemble the pick-up.

Spring

has excess pressure. If the lens is extremely dirty, apply isopropyl alcohol to

the cotton swab.

(Do

not use any other liquid cleaners, because they will damage the lens.) Take

care not to use too much of this alcohol on the swab, and do not allow the

alcohol to get inside the pick-up.

Hidden key mode

Push

both Front key and RCU key to activate it for 5 seconds.

1. Disc Lock On/Off (CD Function Only

Active)

2. Front Key : STOP

RCU

Key :STOP

2. Check Version and Option code

Front Key : STOP

RCU Key : PLAY/PAUSE

You can change [Audio MCU Version <-> CD

Controller Version <-> EEPROM Option] by SKIP+/-.

3. Clear EEPROM

Front Key : STOP

RCU Key : SKIP- (CD Model), 0 (DVD Model)

4. Edit EEPROM

Front Key : STOP

RCU Key : SKIP+

You can change the digit of option by SKIP+/-.

You can edit 0~f by REPEAT or PLAY/PAUSE key.

5. Measure Mode (Bypass)

Front Key : STOP

RCU Key : 8

HW output measure

Service information for EEPROM

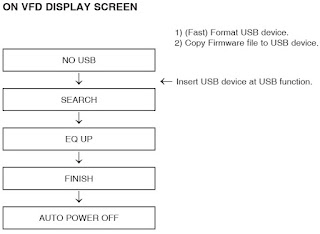

Program download: AUDIO

PROGRAM

Download

program file name must be MICOM_OM7560_YYMMDDX.HEX

If

security program(Water Wall) is activated on PC, you must save the file to the

USB storage device and disable the security software, then download the file to

your set.

Downloading

file proceeds in the same way at USB1 function and USB2 function.

Caution:

When downloading the file, you should neither unplug the USB device, change to

the other function, nor power off the device. USB device must be unplugged when

the downloading process is completed.

CD PROGRAM

Download

program file name must be HG690_OM7560_YYMMDDX.bin

If

security program(Water Wall) is activated on PC, you must save the file to the

USB storage device and disable the security software, then download the file to

your set.

Downloading

file proceeds in the same way at USB1 function and USB2 function.

Caution:

When downloading the file, you should neither unplug the USB device, change to

the other function, nor power off the device. USB device must be unplugged when

the downloading process is completed.

EQ PROGRAM

Download

program file name must be EQ_PRG.BIN

If

security program(Water Wall) is activated on PC, you must save the file to the USB

storage device and disable the security software, then download the file to

your set.

Downloading

file proceeds in the same way at USB1 function and USB2 function.

Caution:

When downloading the file, you should neither unplug the USB device, change to the

other function, nor power off the device. USB device must be unplugged when the

downloading process is completed.

DISASSEMBLY

When

disassembling the Frame Top, do not rotate and disassemble by pulling upwards.

To

disassemble the Front Panel, remove the two screws and disassemble.

Troubleshooting: NO POWER

If

the unit doesn’t work by no power problem, repair the set according to the

following guide.

FUSE/ THERMISTOR/ BRIDGE DIODE

Please

check and replace F901, TH901 or TH903, BD901 on SMPS board.

How

to troubleshoot (Countermeasure)

1)

Check if the fuse F901 is open or short-circuit.

2)

Check if the NTC thermistor TH900 or TH903 is normal or open.

3)

Check if the bridge diode BD901 is short-circuit by over current with a digital

multi-meter.

No power

If

the unit doesn’t work by no PVDD problem, repair the set according to the

following guide.

FUSE/ FET

Please

check and replace F901, Q901 on SMPS board.

1)

Check if the fuse F901 is open or short-circuit.

2)

Check the anode-cathode voltage of D951 with a digital multi-meter, it is

normally 0.2 ~ 0.3 V.

If it doesn’t have any voltage, it’s

destroyed. Replace it with a new one.

No booting when power on the set

The

set doesn’t work when press the power button on the top board or the remote

control.

IC501

Replace

IC501 on MAIN board.

1)

Check the +12 VA (CN202) and 3.3VA (IC503) in standby mode.

If there is no 12 VA, check the SMPS and if

doesn’t appear 3.3 VA, check IC503.

2)

Check +12 VA, +5.1 VA, 3.3 VA, DVCC_5V and DVCC_3.3V when power on the set.

-

If the set doesn’t work regardless of what the KEY1 changes high to low while

pressing the power button.

X500

and X501 work normally but, if you can not power on the set, replace the IC501

with a new one on the main board

VFD is not displayed when power on the set

When

power on the set, any icons or characters on VFD are not displayed.

VFD (VFD301)

Please

check and replace VFD301 on TOP FRONT board.

1)

Check if VFD_12V, DVCC_3.3V and VCC_5V are output from SMPS to VFD via the main

board.

2)

Check if the IC501 outputs VFD_CLK, VFD_STB, and VFD_DAT to the top board.

3)

Check if the VFD grid current amplifier circuit on the top board.

Check

the drive signal to the transistor’s (Q801,2) base.

If the control signals from VFD (DGND, VDD)

isn’t output, replace VFD with a new one.

No booting in CD/USB function

After

you turn on power key and displayed message in the following order (HELLO >

VOL XX >CD or USB) on VFD, it will not display other message on VFD, and it

will not boot-up normally.

NO

DVCC_3.3V, 1.2 VA

Please

check and replace IC202, IC205 on MAIN board.

1)

Check Voltage of IC202 pin3 on MAIN board.

If IC202 pin3 (about 5.1 V) & pin1 Input

12 VA doesn’t come out, check +12 VA from SMPS board.

2)

If IC202 pin3 (about 5.1 V) is normal, check voltage of IC205 pin3 (about 1.2

VA), pin6 (about 3.3 VA). If IC205 pin3

(about 1.2 VA), pin6 (about 3.3 VA) doesn’t come out, check R253, R254, R256

and R260, R261, R262.

If

there’s no defective component then replace IC205.

3)

PWR_CTRL is high, check R512 and if there’s no defective component then replace

IC505.

PWR_CTRL

(IC505 pin3) is high (about 3.2 V)

If

PWR_CTRL isn’t high, check pin D11 of IC501 & R512, R513

4)

If PWR_CTRL is high, check R559 and if there’s no defective component then

replace IC505

NO BOOTING (IN CD/USB FUNCTION)

After

you turn on power key and displayed message in the following order (HELLO >

VOL XX >CD or USB) on VFD, it will not display other message on VFD, and it

will not boot-up normally.

CRYSTAL

(X500)

Replace

X500 on MAIN board.

1)

If 3.3 VA & 1.2 VA is normal, check reset ‘High’ of IC501 pin T12 on MAIN

board.

If MAIN_RESET isn’t high, check MICOM (IC101)

pin40.

2)

If MAIN_RESET is high, check the soldering status of 24 MHz crystal (X500).

3)

If the crystal (X500) doesn’t oscillate, check R508, C502, C503 around crystal

(X500).

If there’s no defective component, then

replace X500.

NO BOOTING (IN CD/USB FUNCTION)

After

you turn on power key and displayed message in the following order (HELLO >

VOL XX > CD or USB) on VFD, it will not display other message on VFD, and it

will not boot-up normally.

SERIAL FLASH (IC503)

Please

check and replace IC503 on MAIN board.

1)

If the crystal (X500) does oscillate, check serial flash (IC503) on MAIN board.

Check

pin8 (VCC), pin6 (CLK), pin1 (CS), pin2 (DO), pin5 (DI) of below waveform.

2)

If pin1, 2, 5, 6 doesn’t come out, check registers (R563, R564, R534, R535,

R536, R5E4) of IC503.

If registers of IC503 is OK, then replace

IC503. (it need to download program.)

3)

After change IC503, if It is still not below waveform, check IC501 (DSP IC).

NO OPERATION OF MD

When

no sound output in the CD function, you can not listen to music reading data

from a CD disc if the servo motors in MD don’t work. This step is for checking

the SPINDLE MOTOR among them.

SPINDLE

MOTOR

Replace

IC400 on MAIN board.

1)

Check the SPDO signal from pin16 of IC401.

If no signal, check DVCC_3.3V and DV 3.3V (RF)

and X400.

2)

Check the SPIN+ & SPIN- from IC400 to CN401 for driving SPINDLE motor. It

is about 3.6 Vp-p.

If no signal, check M_5 V for IC400.

3)

Check if the FFC cable is solidly connected between CN401 and MD.

4)

Check the MD.

If the spindle motor is sort-circuit or has

any trouble, it cannot rotate CD discs.

Please

check the function after changing another MD

NO OPERATION OF MD

When

no sound output in the CD function, you can not listen to music reading data

from a CD disc if the servo motors in MD don’t work. This step is for checking

the SLED MOTOR among them.

SLED MOTOR

Replace

IC400 on MAIN board.

1)

Check the SLDO signal from pin15 of IC401.

If

no signal, check DVCC_3.3V and DV 3.3V(RF) and X400.

2)

Check the SPED+ & SLED- from IC400 to CN401 for driving SPINDLE motor. It

is about 2.9 Vp-p.

If

no signal, check M_5 V for IC400.

3)

Check if the FFC cable is solidly connected between CN401 and MD.

4)

Check the MD.

If

the spindle motor is sort-circuit or has any trouble, it cannot rotate CD

discs.

Please

check the function after changing another MD

NO OPERATION OF MD

When

no sound output in the CD function, you can not listen to music reading data

from a CD disc if the servo motors in MD don’t work. This step is for checking

the TRAY OPEN / CLOSE MOTOR among them.

TRAY

OPEN/ CLOSE MOTOR

Replace

IC400 on MAIN board.

1)

Check MOT_OPEN & MOT_CLOSE signals from pin P5, L4 of IC501 to IC400.

If

no signal, check M_5V to IC400.

2)

Check LOAD± from IC400 to CN401 for driving the tray open / close motor. It is

about 3.85 Vp-p.

If no signal, check M_5V to IC400. If it has

any trouble, replace it with a new one.

3)

Check if the FFC cable is solidly connected between CN401 and MD.

4)

Check the MD.

If

the tray motor is sort-circuit or has any trouble, it cannot open or close the

tray.

Please

check the function after changing another MD

NO OPERATION OF MD

When

no sound output in the CD function, you can not listen to music reading data

from a CD disc if the pickup module in MD doesn’t work. This step is for

checking the LASER TRACKING ACTUATOR.

LASER TRACKING ACTUATOR

Replace

IC400 on MAIN board.

The

tracking actuator makes the laser beam be positioned in the centre of a track

on CD disc.

1)

Check the TRD signal from pin14 of IC401.

If

no signal, check DVCC_3.3V & DV_3.3V (RF) and X400.

2)

Check TR- & TR+ from IC400 to CN400 for driving the tracking actuator.

If

no signal, check M_5V for IC400.

3)

Check if the FFC cable is solidly connected between CN400 and MD.

4)

Check the MD.

If the pickup module has any trouble, it cannot

move the laser beam on the left or right side.

Please

check the function after changing another MD.

NO OPERATION OF MD

When

no sound output in the CD function, you cannot listen to music reading data

from a CD disc if the pickup module in MD doesn’t work. This step is for

checking the LASER FOCUSING ACTUATOR.

LASER

FOCUSING ACTUATOR

Replace

IC400 on MAIN board.

The

focusing actuator makes the laser beam keep a regular interval with the surface

of a CD disc.

1)

Check the FDO signal from pin13 of IC401.

If

no signal, check DVCC_3.3 & DV_3.3V(RF) and X400.

2)

Check F- & F+ from IC400 to CN400 for driving the focusing actuator.

If

no signal, check M_5V for IC400.

3)

Check if the FFC cable is solidly connected between CN400 and MD.

4)

Check the MD.

If the pickup module has any trouble, it cannot

move the laser beam on the top or bottom side.

Please

check the function after changing another MD

NO SOUND

There

is no sound output by DIGITAL AUDIO AMP DAMAGE, repair the set according to the

following guide.

DIGITAL

AUDIO AMP DAMAGE

Replace

IC701, IC702 on MAIN board.

1)

Check PWM_FL±, PWM_FR± & PWM_SW± signals from IC601 to IC701 & 702 each

input function.

If

no signal, check if I2S audio signals are entered to IC601.

2)

Check PVDD.

If

PVDD is abnormal, check the SMPS.

3)

Check AMP_12V for driving the gate of AMP IC.

a.

All the powers are normal, but if AMP_12V is low, there is possible for AMP IC

to be damaged.

b.

Remove L701, L702, L703 and L704 one by one.

When

removed a inductance, if AMP_12V is recovered, the IC connected to it was damaged.

c.

Replace the IC with a new one.

4)

Check the impedance between IC701/IC702_OUT_A/OUT_B & GND.

a.

If the impedance is 0 Ω, the IC must be damaged.

b.

After removing the heat sink, replace it with a new one

NO SOUND

There

is no sound output in the CD FUNCTION, repair the set according to the

following guide.

CD

FUNCTION

Replace

IC501 on MAIN board.

1)

Check CD_BCK, CD_LRCK, & CD_DATA signals from IC501 to IC401.

If

no signal, check if the RF & servo signals from MD is entered to IC401.

Refer

to the “No operation of MD” guide on Item 5.

2)

Check the following I2S signal flow. < I2S audio signal Interface >

-

MCS_BCK : IC501_pin E1 --> IC601_pin23

-

MCS_LRCK : IC501_pin D1 --> IC601_pin22 (44.1 kHz)

-

MIX_DATA0_OUT : IC501_pin E2 --> IC601_pin24

-

MCS_MCLK : IC501_pin D2 --> IC201_pin44

If there is any trouble, check the power for

each IC.

The

power is normal but, if the signal waveform to the IC is distorted or no

signal, replace it with a new one

NO SOUND

There

is no sound output in the USB Function, repair the set according to the

following guide.

USB FUNCTION

Replace

IC204 on MAIN board.

1)

Check +5V_USB to USB board.

If the USB LED are turned on, the voltage is

okay, if so not, check USB_5V to pin5, 6 of CN803.

2)

Check USB D1± or USB D2± from MAIN board to TOP board.

a.

Check 2.0_D1±signals (pin U7, U8 ) or 1.1_D1± signals(pin A7, A8 ) to IC501.

b.

Check USB± signals to CN502 (pin1, 2, 8, 9).

If there is any trouble, check the power for

IC204.

The

power is normal but, if the signal waveform to the IC is distorted or no

signal, replace it with a new one.

3)

Check if “Digital audio AMP block” on item 6-1 is normal.

NO SOUND

There

is no sound output in the AUX Function, repair the set according to the

following guide.

AUX

FUNCTION

Replace

IC201 on MAIN board.

1)

Check AUX_L/R signals to IC201 (pin23, 24).

2)

Check if MCS_BCK, MCS_LRCK & MCS_MCLK are entered from IC501 to IC201.

3)

Check if ADC_DATA is entered from IC201 to IC501.

If no signal, check DVCC_5V & DVCC_3.3V

(ADC) for IC201. If is NG, replace it a new one.

4)

Check the following I2S signal flow from IC501 to IC601. (Refer to Item 6-2.)

If there is any trouble, check the power for

each IC. The power is normal but, if the signal waveform to the IC is distorted

or no signal, replace it with a new one.

5)

Check if the digital audio AMP block is okay. Refer to “Digital Audio AMP”

guide on Item 6-1.

If AMP is damaged, replace it with a new one.

NO SOUND

There

is no sound output in the TUNER function, repair the set according to the

following guide.

TUNER FUNCTION

Replace

IC201 on MAIN board.

1)

Check if TUNER_LR is entered from pin1, 3 of TU500 to IC201 (pin26, 27).

if no signals, check DVCC_3.3V for tuner

power.

Check if the tuner control signals (CLK, DAT,

CE, RST, SLT) are entered from IC501 to TU500.

If

it doesn’t work, replace TUNER with a new one.

2)

Check if MCS_BCK, MCS_LRCK, & MCS_MCLK are entered from IC501 to IC201.

3)

Check if ADC_DATA is entered from IC201 to IC501.

If

no signal, check DVCC_5V & DVCC_3.3V (ADC) for IC201. If is NG, replace it

with a new one.

4)

Check the following I2S audio signal flow from IC501 to IC601. (Refer to Item

6-2.)

If there is any trouble, check the power for

each IC.

The

power is normal but, if the signal waveform to the IC is distorted or no

signal, replace it with a new one.

5)

Check if the digital audio AMP block is okay. Refer to “Digital Audio AMP”

guide on Item 6-1.

If AMP is damaged, replace it with a new one.

NO SOUND

There

is no sound output in the PORTABLE Function, repair the set according to the

following guide.

PORTABLE

FUNCTION,

Replace

IC201 on MAIN board.

1)

Check if PT_LR signals to IC201 (pin9, 10).

2)

Check if MCS_BCK, MCS_LRCK, & MCS_MCLK are entered from IC501 to IC201.

3)

Check if ADC_DATA is entered from IC201 to IC501.

If no signal, check DVCC_5V & DVCC_3.3V

(ADC) for IC201. If is NG, replace it with a new one.

4)

Check the following I2S audio signal flow from IC501 to IC601. (Refer to Item

6-2.)

If there is any trouble, check the power for

each IC.

The

power is normal but, if the signal waveform to the IC is distorted or no

signal, replace it with a new one.

5)

Check if the digital audio AMP block is okay. Refer to “Digital Audio AMP”

guide on Item 6-1.

If

AMP is damaged, replace it with a new one.

NO SOUND

There

is no sound output in the MIC IN function, repair the set according to the

following guide.

MIC

IN function

Replace

IC206 on MAIN board, ICA301 on TOP FRONT board.

1)

Check MIC_SI & MIC_S2 signal to pin5 & 6 of CN201.

If

no signal, Check the signals to pin6 & 8 of CNA301 on the FRONT board.

Check

if the signal is entered from pin 6 & 8 of CNA301 to pin 5 & 6 of

CN201.

2)

Check if MIC_SIG is entered from pin 6 of JK302 & JKA303 to pin2, 13 to

ICA301 (PRE AMP).

3)

Check if the amplified signal comes out from pin3 &12 of ICA301.

If

no signal output, check DVCC_3.3V for ICA301, replace ICA301 with a new one if

it has a problem.

4)

Check if MCS_BCK, MCS_MLCK & MCS_LRCK is entered from IC501 to IC206.

Check

if MIC_DATA_IN is entered from pin9 of IC206 to pin T1of IC501.

If no signal, check DVCC_5V & DVCC_3.3V

for IC206.

If

it is abnormal, change replace it a new one.

5)

Check the following I2S signal flow from IC206 to IC501.

If

there is any trouble, check the power for each IC.

If

the signals are abnormal, replace it a new one.

6)

Check if the digital audio AMP block is okay. Refer to “Digital Audio AMP”

guide on item 6-1.

If

AMP is damaged, replace it with a new one.

NO SOUND

There

is no sound output in the Bluetooth function, repair the set according to the

following guide.

BLUETOOTH

FUNCTION

Replace

IC501 on the MAIN board or Bluetooth module on the FRONT Panel.

1)

Check BT_RX, BT_TX signal to pin6, 4 of CN504.

If no signal, check the signal to pin4, 6 and

pin10 (BT_3.3V) of on the Bluetooth module and cable connection state.

If

there are no signal out from module, replace new module.

2)

Check if BT_RX/TX is entered from pin6, 4 of CN504 to pin L1,K1 to IC501 (DSP).

3)

Check if MCS_BCK, MCS_LRCK & MIX_DATA IN is entered from IC501 to IC601.

If

no signal, check +3.3 VA & +1.2 VA for IC501.

If

it is abnormal, change replace it a new one.

4)

Check the following I2S signal flow from IC501 to IC601.

If

there is any trouble, check the power for each IC.

If

the signals are abnormal, replace it a new one.

5)

Check if the digital audio AMP block is okay. Refer to “Digital Audio AMP”

guide on item 6-1.

If

AMP is damaged, replace it with a new one

Circuit voltage chart

Connector voltage chart

DECK MECHANISM DISASSEMBLY

1.

Main Base (Fig. 4-1)

1-1.

Clamp Assembly Disc

1)

Place the Clamp Assembly Disc as Fig. (A)

2)

Lift up the Clamp Assembly Disc in direction of arrow(A).

3)

Separate the Clamp Assembly Disc from the Holder Clamp.

1-1-1.

Plate Clamp

1)

Turn the Plate Clamp to counter clockwise direction and then lift up the Plate

Clamp.

1-1-2.

Magnet Clamp

1-1-3.

Clamp Upper

2.

Tray Disc (Fig. 4-2)

1)

Insert and push a Driver in the emergency eject hole(A) at the right side, or

put the Driver on the Lever(B) of the Gear Emergency and pull the Lever(B) in

direction of arrow so that the Tray Disc is ejected about 15~20mm.

2)

Pull the Tray Disc until it is separated from the Base Main completely.